- Plate Bevelling

- Automatic Plate Bevellers

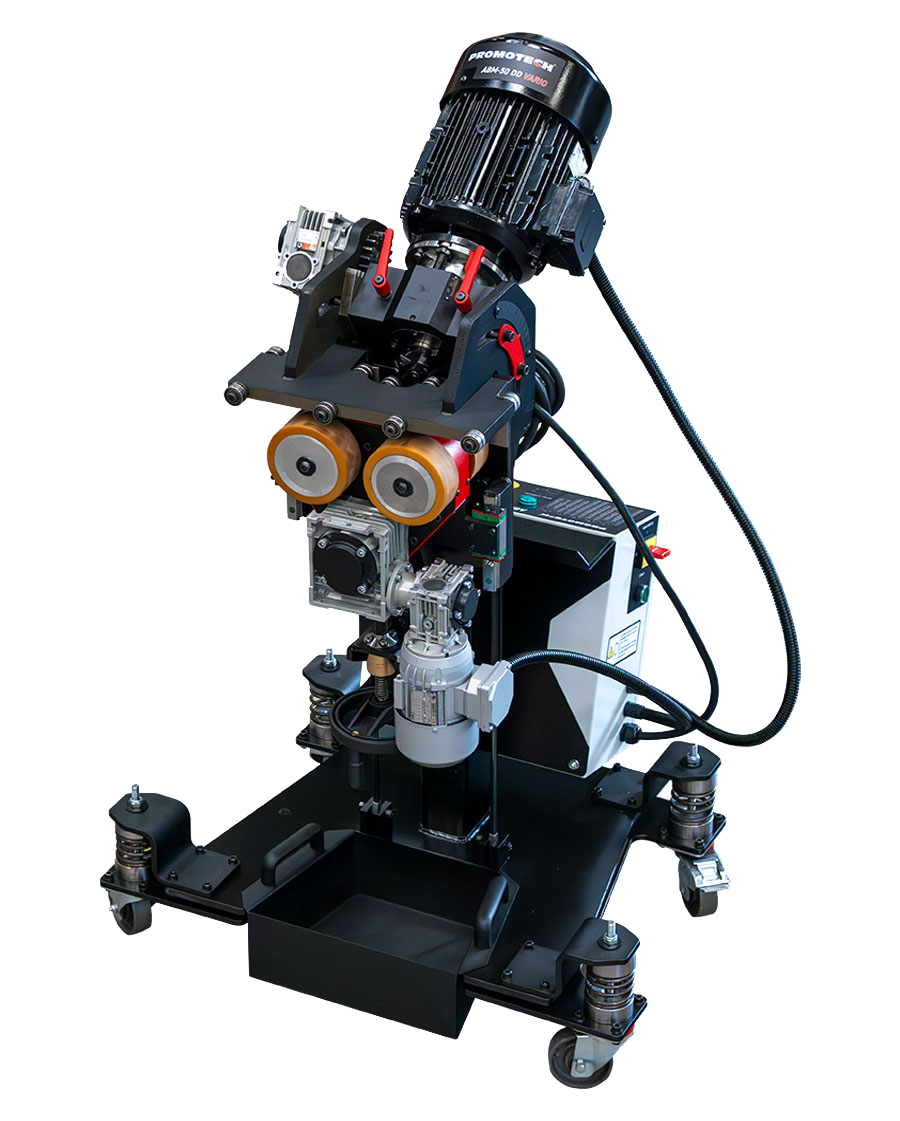

- ABM-50 DD Vario Auto-Feed Heavy Duty Beveller

ABM-50 DD VARIO AUTO-FEED HEAVY DUTY BEVELLER

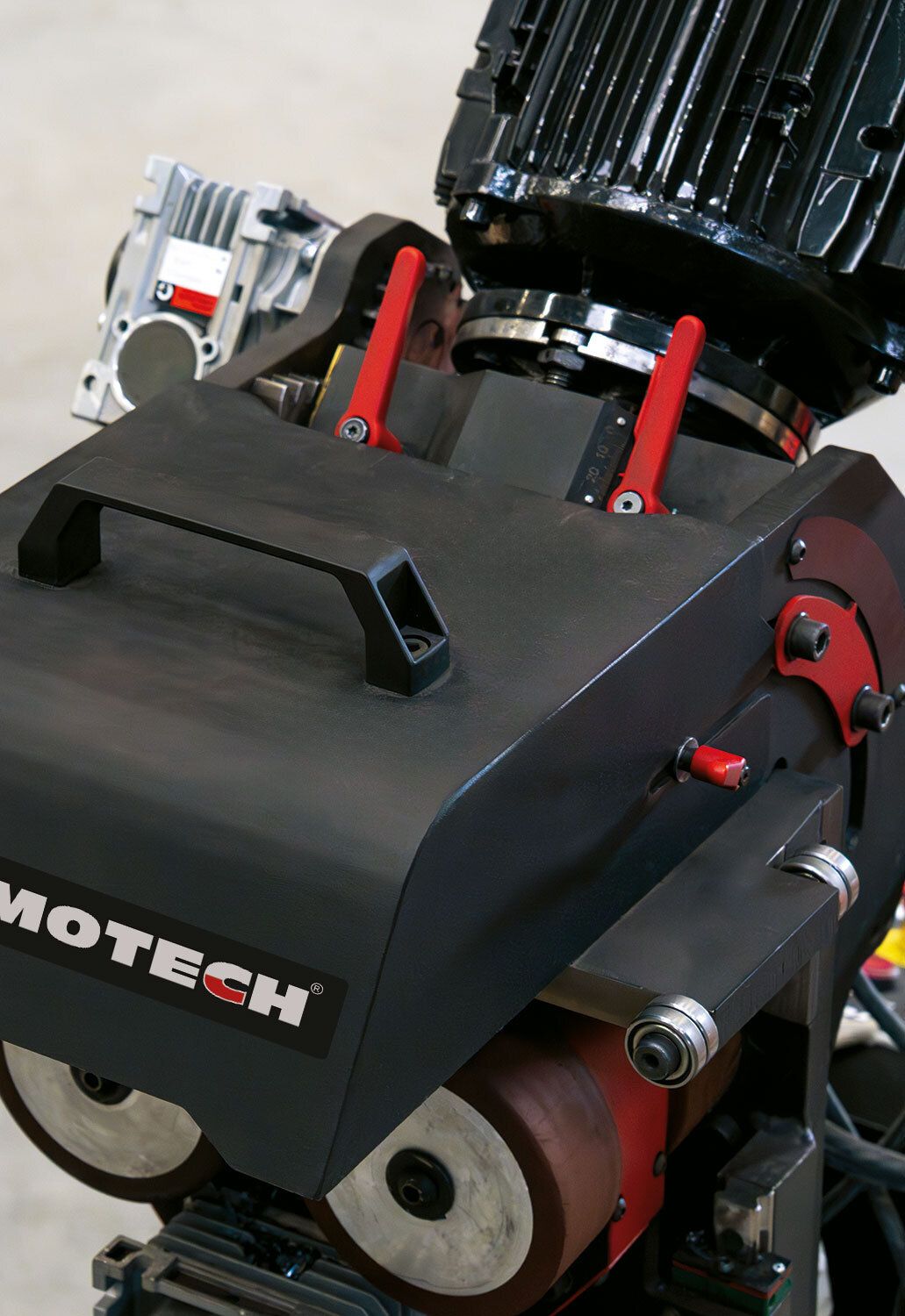

Featuring load level LED monitoring system

ABM-50 DD Vario is the self-propelled bevelling machine that produces high-quality bevels up to 50 mm wide without thermal distortion or the creation of heat heat-affected zone on the top edge of plates from 8 mm to 80 mm thick. Adjustment of spindle speed and feed rate, together with a load level LED monitoring system, helps to optimise cutting conditions depending on the grade of material, including stainless steel, duplex, alloys, Hardox and many others.

The ABM-50 DD Vario allows continuous adjustment of the bevel angle over a wide range from 15 to 70°. If you're only bevelling carbon steel, you can opt for the basic ABM-50 DD model with a fixed spindle speed.

Want to make sure the 'ABM-50 DD Vario Auto-Feed Heavy Duty Beveller' is right for you? Speak to our specialist solutions team today.

FIND OUT MORE PURCHASE OR HIRE WATCH VIDEO

Top bevelling

Min plate thickness 8 mm Max plate thickness 80 mm

Bevel angles top 15° - 70°

Bevel width up to 50 mm / 45°

FEATURES

- Self-propelled machine moves along the edge of the plate at speeds of up to 1.2 m/min.

- Auto-feed machining to increase ergonomics, comfort, and productivity.

- Continuous bevel angle adjustment from 15° to 70°.

- High-quality bevels made without thermal distortion or creation of heat-affected zone on plate thickness range 8-80 mm.

- Continuous bevel width adjustment up to 50 mm at 45 degrees.

- Variable spindle speed for machining a wide range of steel grades.

- LED monitoring system indicates the load level using green, yellow and red signals to prevent motor damage.

Specification

| Model | ABM50 DD Vario |

| Weight | 260 KG |

| Maximum Bevel Cut Width | Width 50 mm |

| Bevel Angle | 15-70° |

| Material Thickness | 8 to 80mm |

| Motor Power | 4000 Watt / 400v 3 phase |

| Cutting Speed | 0-1.2 m |

| Spindle rotational speed (without load) | 500-1450 rpm |

| Feed speed | 0-1.2 m/min |

| Maximum milling head penetration (‘d’, Fig. 1) per single pass | 6 mm |

| Sheet thickness | 8-80 mm |

| Required ambient temperature | 0-40°C |