JTS

Automated Two-Axis Torch Guidance For Consistent Weld Quality

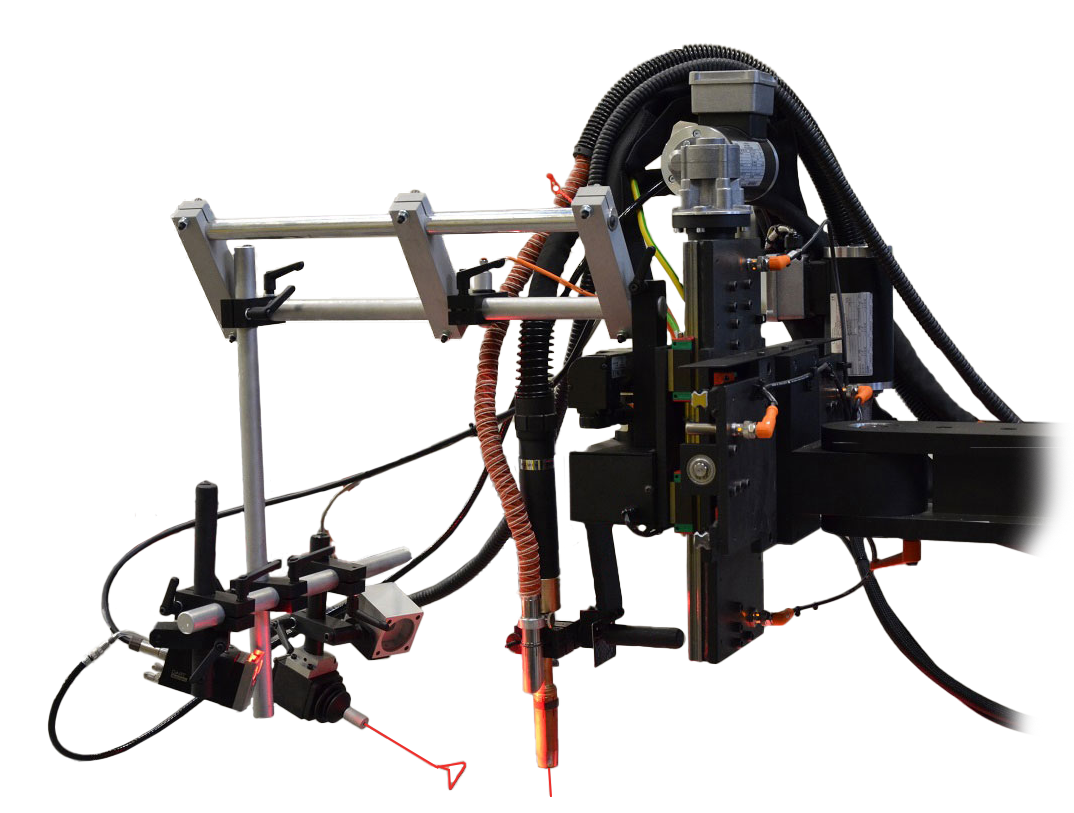

The Automatic Joint Tracking System (JTS) is an automated solution that ensures precise welding torch positioning along two axes (up-down, left-right). Designed to compensate for misalignment or curvature in the workpiece, the JTS continuously tracks the weld joint to maintain exact torch alignment. This eliminates the need for manual torch adjustments, improving accuracy, consistency, and overall weld quality.

Compatible with MIG/MAG and SAW welding, the JTS integrates seamlessly with new or existing column and boom systems, gantry welding setups, or other custom welding configurations.

The cross-slide unit features a universal mounting plate with multiple hole patterns for flexible installation across different welding machines, ensuring quick and easy integration.

For advanced process control, the JTS can be linked with the main welding device’s safety system. In this configuration, the system transmits key data such as:

-

Sensor tension in X and Z axes (analogue voltage)

-

End-of-range detection (potential-free contact)

-

Integration with emergency stop circuits (E-Stops)

This intelligent communication between the JTS and the main welding system enhances both operational safety and process efficiency, making it an essential tool for precision automated welding.

Want to make sure the 'JTS' is right for you? Speak to our specialist solutions team today.

FIND OUT MORE PURCHASE OR HIRE WATCH VIDEO

Specification

| Voltage | 230 V, 50/60 Hz + PE | |

| Power | 500 W | |

| Cross slide vertical movement range (up-down axis)* | 200 mm (7.9’’) | |

| Cross slide horizontal movement range (right-left axis)* | 200 mm (7.9’’) | |

| Cross slide horizontal movement speed (right-left axis) | 360 mm/min (14.2 in/min) | |

| Cross slide horizontal movement speed (X axis) | 360 mm/min (14.2 in/min) | |

| Required ambient temperature | 5–40°C (41–104°F) | |

| Weight | 45 kg (100 lbs) | |

| Integration with external safety devices | YES | |

| * Movement range can be customised upon customer’s request. | ||

Features

| Standard movement range: 200 x 200 mm. |

| An electromechanical joint tracking system with high-precision linear guides ensures accurate and smooth motion in two axes (up-down, right-left). |

| Real-time compensation of head position relative to the welding groove. |

| Minimises welding defects and reduces grinding requirements. |

| Cross slide can be customized to meet customer specifications. |

| Equipped with a user-friendly control pendant. |