- Welding & Cutting Automation

- Welding Automation

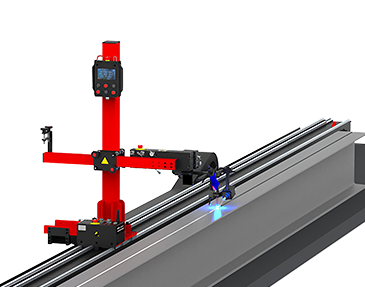

- WA COMPACT

WA COMPACT

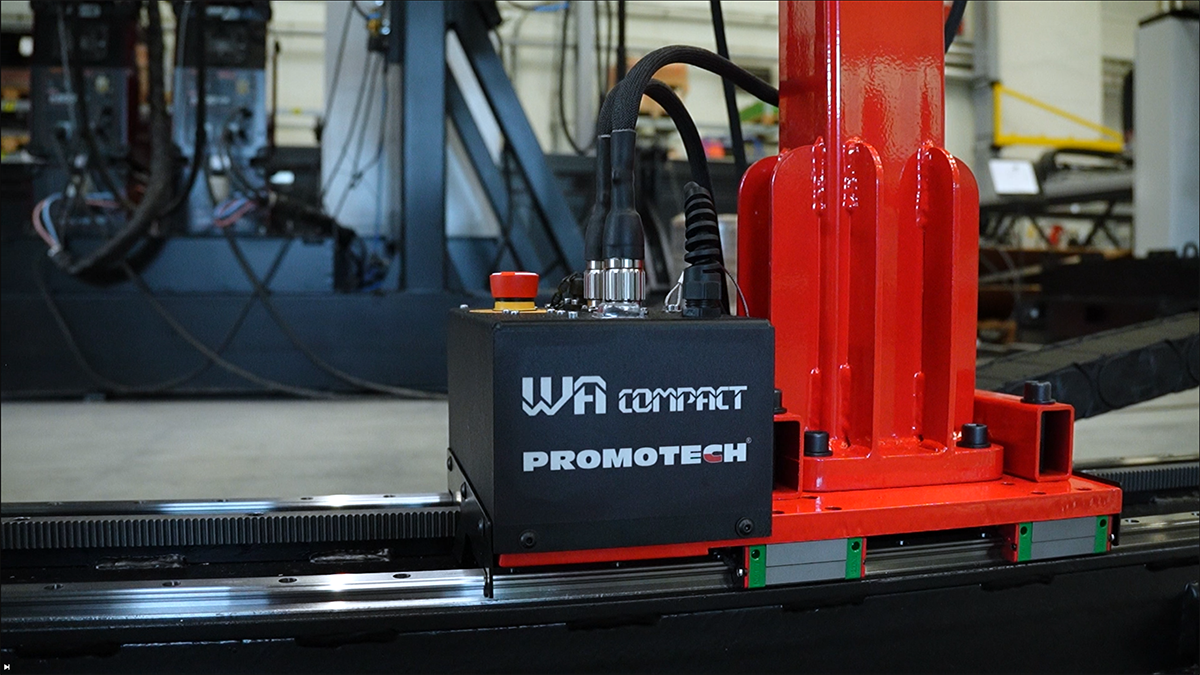

Gantry Welding System

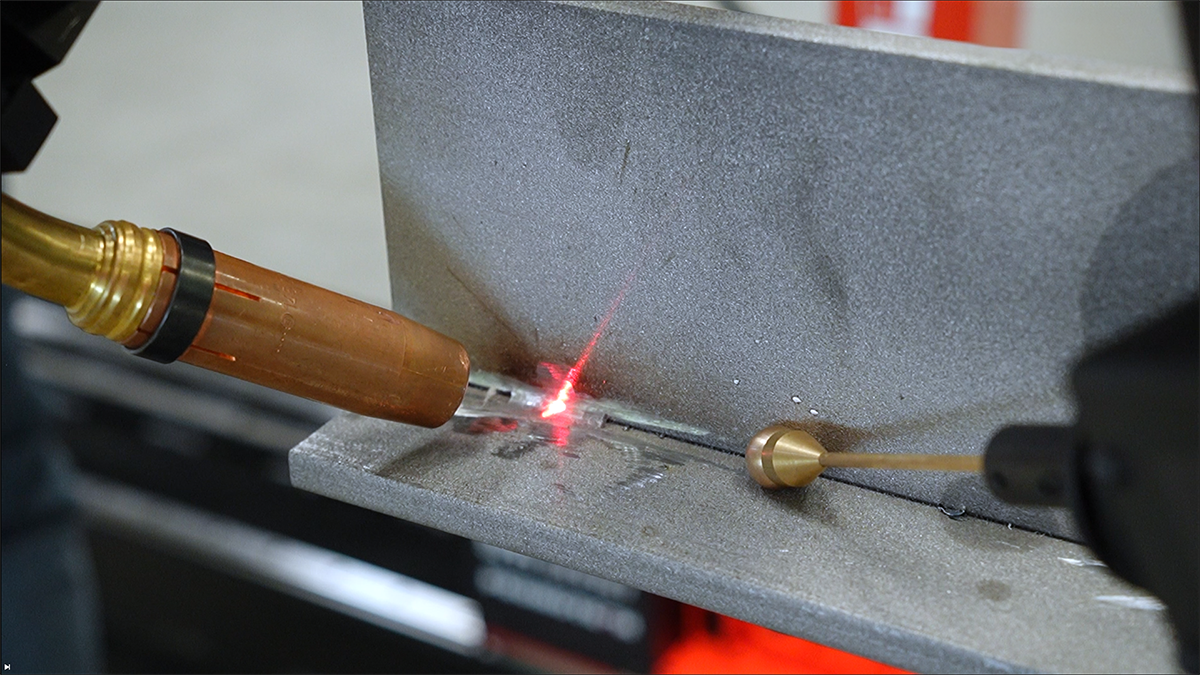

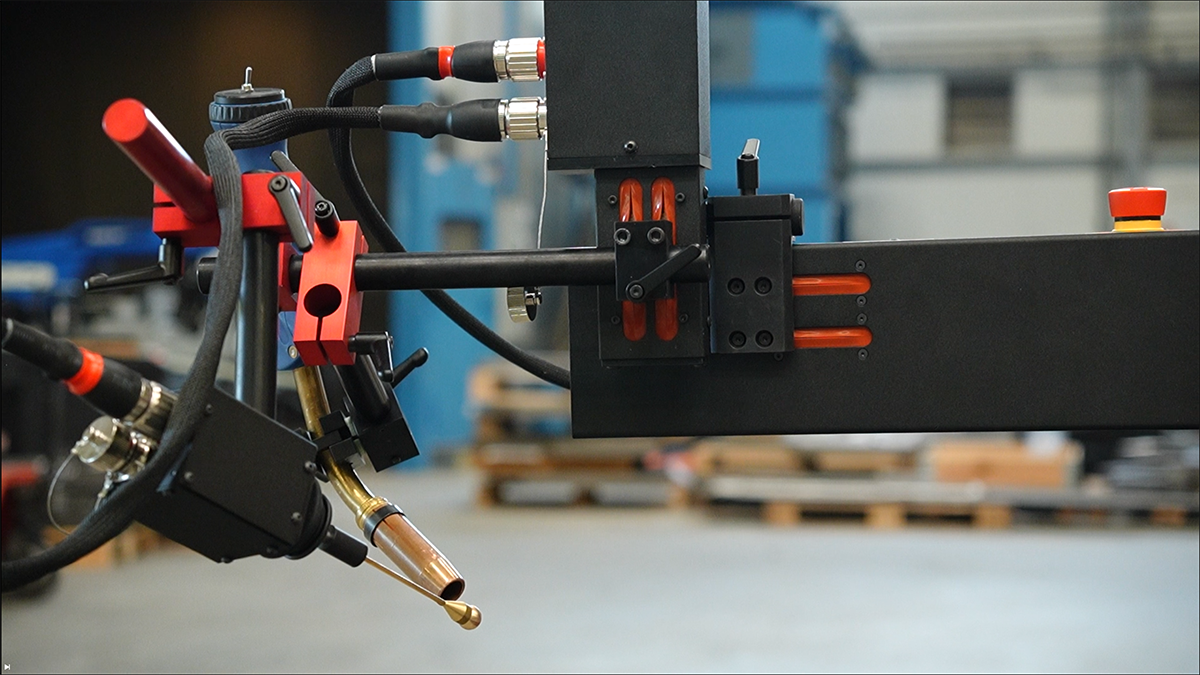

The WA Compact is an advanced and versatile welding solution designed for continuous and stitch butt or fillet welds using the MIG/MAG process.

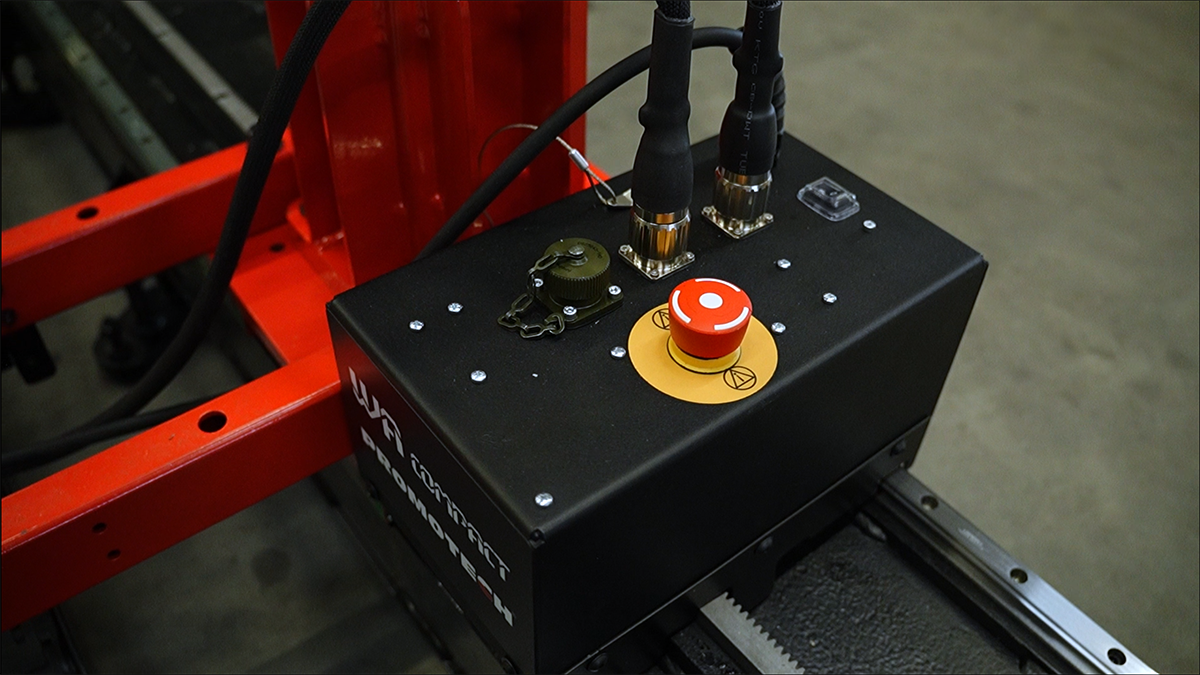

It features pendant-based machine control and provides efficient joint tracking for active torch position compensation, both vertically and horizontally, with or without oscillation.

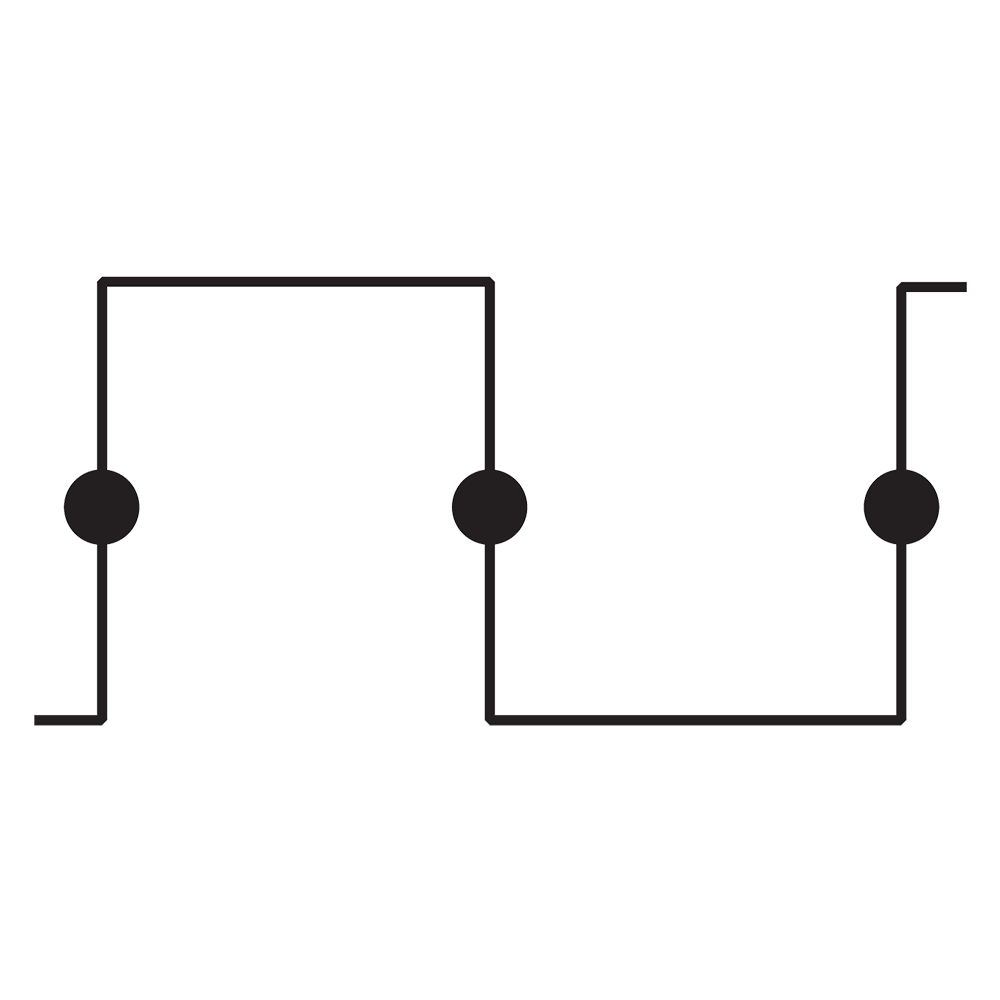

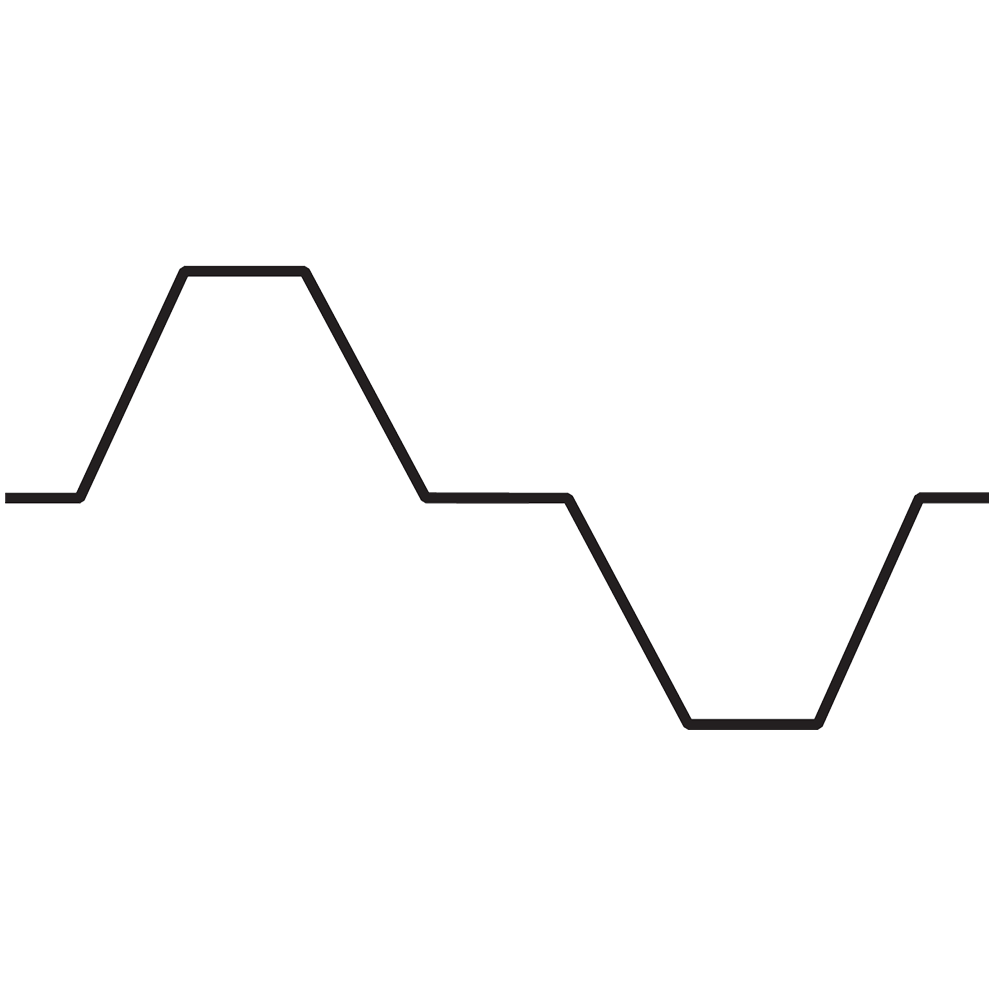

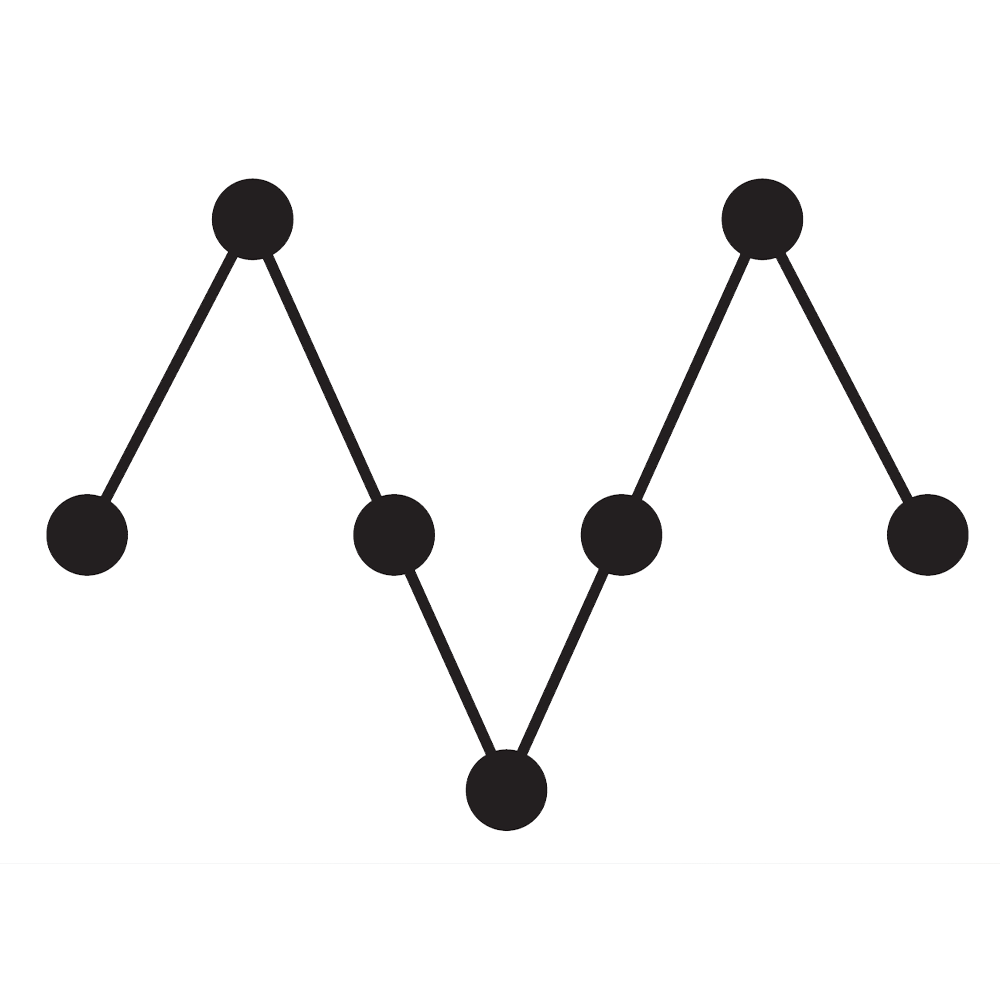

Supporting multiple oscillation patterns, straight, triangle, trapezoid, and square — the WA Compact adapts easily to a wide range of welding tasks.

Ideally suited for industrial use, it offers a highly efficient and cost-effective solution for workshops and large-scale production environments.

Want to make sure the 'WA COMPACT' is right for you? Speak to our specialist solutions team today.

FIND OUT MORE PURCHASE OR HIRE WATCH VIDEO

Edge welding in a flanged butt Joint

Single V Corner Joint

Single Fillet Corner Joint

Single Fillet Lap Joint

Single Fillet Joint

Double Fillet Tee Joint

WA Compact Oscillation Paths

Specification

| Voltage | 1~ 110–120 V, 50–60 Hz |

| 1~ 220–240 V, 50–60 Hz | |

| Power | 200 W |

| Torch type | MIG/MAG |

| MIG/MAG torch diameter | 16–22 mm (5/8”–55/64”) |

| Horizontal speed | 0,05–2,5 m/min (2–98 inch/min) |

| Standard torch travel length * | 3.5 m |

| Standard overall track length * | 4 m |

| * Can be extended by a 2 m long track section to maximum 20 m total length | Option |

| Cable chain in custom lengths on request | Option |

| Rotating module | Option |

| Oscillation type | Linear |

| Weld path | Straight, triangle, trapezoid, square |

| Oscillation width | 0–11,4 cm (0–4 31/64”) |

| Oscillation speed | 0,1–2 m/min (4–79 inch/min) |

| Oscillation dwell time at center and on ends | 0–5 s |

| Maximum oscillator pulling force | 50 N |

| Weight (incl. 4 m standard track length) | 484 kg |

Features

| Precision and efficiency: Oscillation and joint tracking with a motorised vertical slide ensure accurate torch positioning and high-quality welds. |

| Flexible oscillation patterns: Straight, triangle, trapezoid, and square paths for different welding applications. |

| User-friendly control: Ergonomic remote pendant with clearly marked knobs allows adjustments without removing the welding hood. |

| Custom track length: 2 m support segments can be configured to meet specific workspace requirements. |

| Cost-effective solution: Delivers advanced functionality and adaptability at an affordable cost, ideal for workshops and large industrial facilities. |