- Welding & Cutting Automation

- Welding & Cutting Tractors

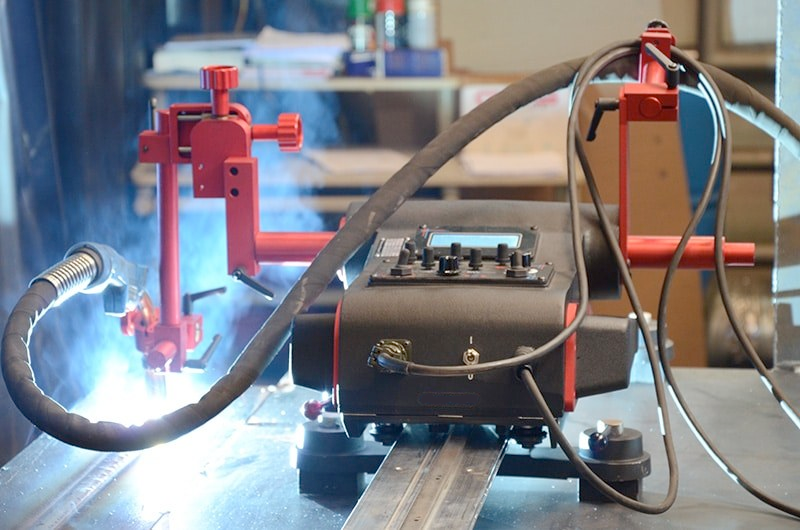

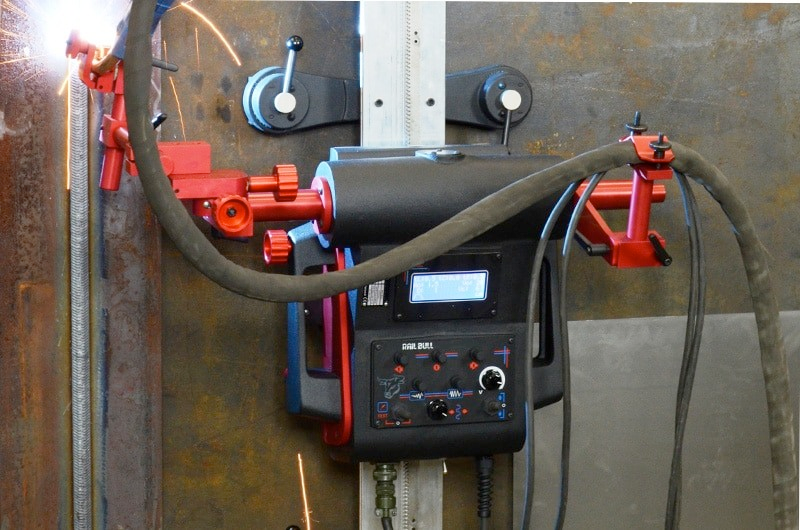

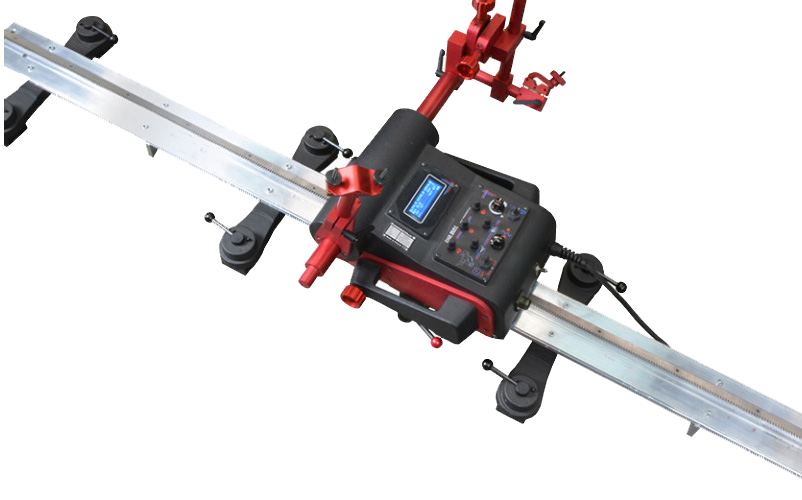

- Rail Bull with Oscillation welding tractor

RAIL BULL WITH OSCILLATION WELDING TRACTOR

A Track Welding Carriage

The specialised Rail Bull is a welding tractor designed to produce butt and fillet welds with oscillation.

The carriage can work in PA (flat), PB (horizontal, vertical), PC (horizontal), PF (vertical), and PG (vertical down) welding positions.

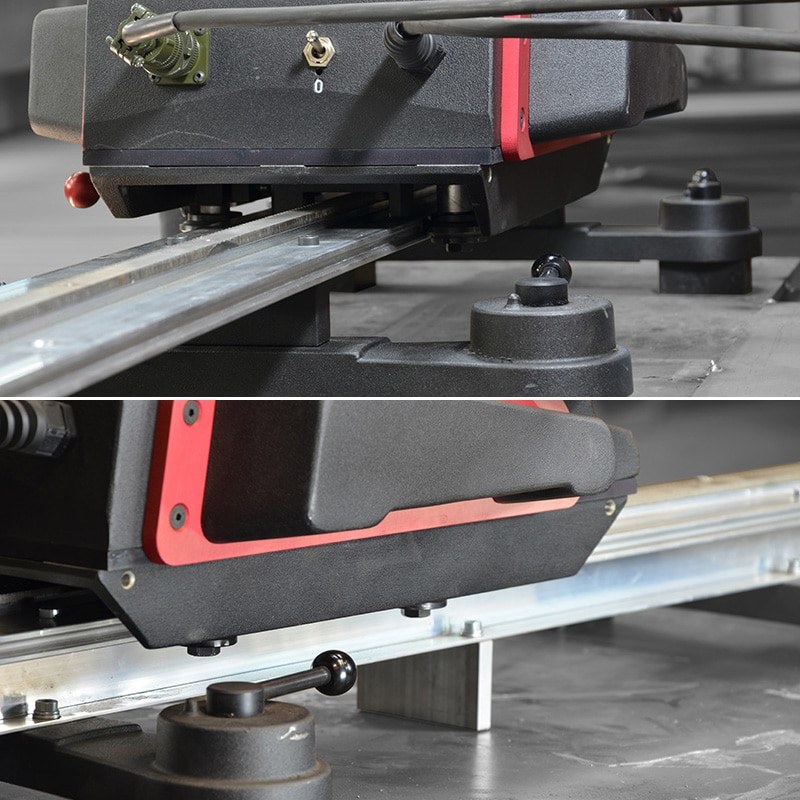

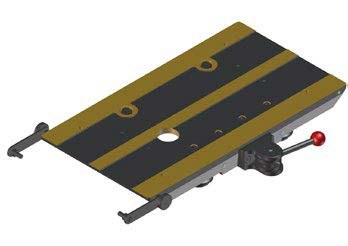

Rail Bull can move along either rigid or semi-flexible track.

Both types of track are fixed to flat or curved ferromagnetic surfaces by means of dual magnetic units (minimum curvature radius 5 meters).

Want to make sure the 'Rail Bull with Oscillation welding tractor' is right for you? Speak to our specialist solutions team today.

FIND OUT MORE PURCHASE OR HIRE WATCH VIDEO

Continuous welding

Linear oscillation

Works in horizontal and vertical positions

Min concave radius 5000 mm

Min convex radius 5000 mm

Straight cutting

Diagonal cutting (bevelling)

Strips cutting

Double diagonal cutting (bevelling)

WHY THE RAIL BULL?

RAIL BULL is a track carriage designed for plate bevelling or establishing groove and fillet welds with oscillation using MIG/MAG welding torches. The machine can work in PA (flat), PB (horizontal vertical), PC (horizontal), PD, PE (overhead), PF (vertical up) and PG (vertical down) welding positions.